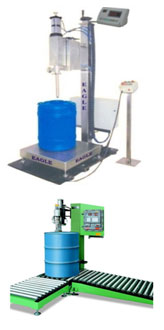

DRUM FILLING MACHINE

Features :

Features :

- Latest Micro Controller based design

- Rugged construction

- ADI Artech (USA) Make Heavy Duty Load cell for rough handling

- Stainless Steel Valve with Teflon coating

- Coarse and fine feed for better accuracy

- Auto calibration (thru Key Pad)

- High internal count greater than 2,00,000 counts

- Data retention in memory even power failure Gross/Net filling.

- Top Rollers and side roller conveyor for easy handling of drums

- In-Mouth filling & hence no spillage

- Local control panel for easy Operation.

- Fill Accuracy : Better than + / - 0.1% FSR

- Display : 0.5 mm height (7 segments LED)

- Load Sensor : Strain Gauge Based Load sensor

- Fill Mode : Auto/Manual

- No. of Fillings : 1 fillings per minute (Depends on the flow available)

- Fill Valve : SS with Teflon Lining

- Operating Temp : 5-50 degree C

- Operating Pressure : 6-8 bar

- Power Supply : 230v Ac, 50 Hz +/- 10%

- Platform Size (mm) : As per Customer Requirement.

Edible Oils, Lubricants, Paints, Chemicals & Other Liquids

Options :Printer interface, Computer interface, Remote Display, Higher Capacity, Flame Proof

| Capacity | Resolution |

| 100 Kg | 20 gm |

| 200 Kg | 50 gm |

| 300 Kg | 50 gm |

| 500 Kg | 100 gm |